Tray Filler

Seed tray filling machine is used to easily to various tray types (e.g. unolith, plastic and polystyrene and etc.) to fill cocopeat, perlite, peat moss, potting soil and others. TIDAPARS automatic Tray filler machine used at greenhouse and nurseries, transplants and cuttings. There are many models, each of them uses a different filling way. In most cases the trays are conveyed to the seed tray filling machine by conveyor belt running underneath a hopper containing soil.

The trays are then filled with soil. Next, a brush removes any excess soil from the tray for a tidy result. In total time the excess soil is returned to the soil hopper.

Screw feeder rotation makes the clots shatter and the soil mix well.

The screws for loading and handling of the soil are in horizontal and vertical way.

Screws are made in steel to resist against torsion, thrusts or stress.

The tray filler ensuring the maximum filling uniformity in every cell.

554 liter hopper.

Automatic cleaning brush.

Extra spiral part to collect excess soil.

Continuous rotary mixer of TIDAPARS:

Continuous rotary mixer, materials that need to be combined, such as cocopeat , perlite, leca, peat moss and etc. Poured from input of machine into the hopper, they are mixed and combined along the machine at the same time as the mixer rotates by the Blades are built along it and move forward. After complete mixing, the growing media is completely uniform and combined from the output part of the machine and ready to fill seed tray filling machine.

Characteristics of TIDAPARS culture media mixer

Power consumption: 1.5 kw.

Power: 3 phase (power requirement: 380 VAC 3~50/60 Hz).

Device dimensions: 200*300*800 cm.

Machine weight: 200 kg.

Seed tray filling machine -soil mixer

A homogenous soil mixer is compliment with soil filling part is a very high efficiency device. No need to monitor the soil mixer unlike a conventional mixer. And as a result, it delivers a full tray of uniform soil.

Seedling tray- tray filler

Using a transplant tray to produce seedlings is a common method in modern agriculture. The plant is highly sensitive in the early stages of growth and it is very important to meet the different needs of the plant at this stage. When growing in a seedling tray, it is possible to take better care so that the plant grows faster, which, as a result, advances the production time of the product.

Culture tray benefits:

The price is right

Easy to move

Multiple use

Reducing the incidence of diseases

Good drainage

Proper ventilation

Accelerating seed growth

Types of trays

Unolith (Styrofoam) culture trays-tray filler:

Adaptable in different weather conditions

High resistance

Easy transportation

High planting density

Low weight

Suitable for propagating vegetables, flowers, etc.

Moisture retention (due to foam insulation)

Saving on cultivation costs

Polystyrene culture tray-tray filler:

Variety of colors

High quality and longevity

Has suitable volumes

Its price is very affordable

Ability to disinfect several times

Heat exchange and effect on transplant

Increase production efficiency

Anti-UV properties

Easy separation from the tray

Impact of growing media to the yield quality

Worldwide, a high percentage of the hydroponic systems uses mineral culture media such as vermiculite, urea formaldehydes and perlite, while just nearly 12% uses organic culture media such as peat moss, cocopeat, barks and others.

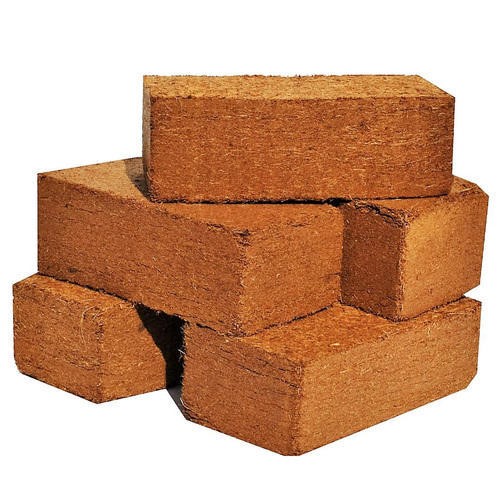

The most practical culture media for hydroponic greenhouses is cocopeat and perlite that used in seed tray filling machine of TIDAPARS (see Fig.8).

Application of perlite in horticulture

Although perlite is essentially chemically and biologically inert, making it free of any potential pests, diseases, and weed seeds. Perlite is a Very effective material used to reduce cooling losses or heat leak into the culture media.

In horticulture, perlite is known in the world as a component of hydroponic culture media and provides ventilation and moisture retention for seeds and for rooting cuttings.

Application of cocopeat in horticulture

Cocopeat multipurpose benefits include high soil moisture retention, soil conditioning, earthworm bedding, compost filler and growth media for soil-less culture.

Despite having such valuable properties, cocopeat cannot be recommended for agricultural use alone due to its high value lignin and cellulose content. The use of cocopeat in combination with perlite and other composts has proven to be an excellent medium culture, source of plant growing media in hydroponic cultures systems.

The raw cocopeat should be washed in water to reduce its salt for reducing the EC which is then dried and subjected to sieving-mixing process.

Perlite and cocopeat used in seed filler:

Prior to all cultivation trays are filled with a substrate. To achieve a successful growth of the root system of the plant, a tray must be filled with the correct density level. Due to perlite and cocopeat availability, price and superior properties, it’s the most common lightweight filler used for these applications.

What’s the use of applying perlite in seed tray filling machine?

Neutral ph.

Sterile.

Weed-free.

Light weight makes it ideal for use in seed tray.

Carrier for fertilizer, herbicides and pesticides.

Benefits of coco peat using in seed tray filling machine:

Renewable resource (100% Organic).

Uniform in Composition.

Odorless.

Good drainage.

Good aeration.

High water holding capacity.

Great absorption.

Promotes strong root growth.

Affordable and High Quality.

Conclusion

To achieve a successful growth of the root system of the plant, a tray must be filled with the correct density level. Perlite and cocopeat are growing media type for hydroponic culture systems. The soil nutrition system in this collection is helical. This helix made of corrosion and pressure resistant material is effective in the speed of operation and high quality of work. In designing TIDAPARS tray filling machine, we have taken all of aspects into careful consideration to ensure optimal growth for seeds. After filling, the trays are brushed and deliver a clean and uniform result by TIDAPARS seed tray filling machine.

♦ Fatemeh safae- faegheh osanlou

www.tidapars.com

TIDAPARS

Tell: 00989904823436

Tell: 00989103218552