Do you know what a bundling machine is?

A bundling machine is a type of packaging equipment used to wrap or bundle items together. These machines are commonly used in manufacturing, shipping, and warehouse operations to efficiently package and transport items.

There are various types of bundling machines, including stretch film bundling machines, strapping machines, and shrink wrapping machines. Stretch film bundling machines use a plastic stretch film to tightly wrap and secure items together, while strapping machines use straps made of plastic or metal to hold items in place. Shrink wrapping machines use heat to shrink a plastic film around items, creating a tight and protective seal.

Bundling machines can greatly increase efficiency and productivity in packaging operations, as they are able to quickly and consistently package items in a secure and organized manner.

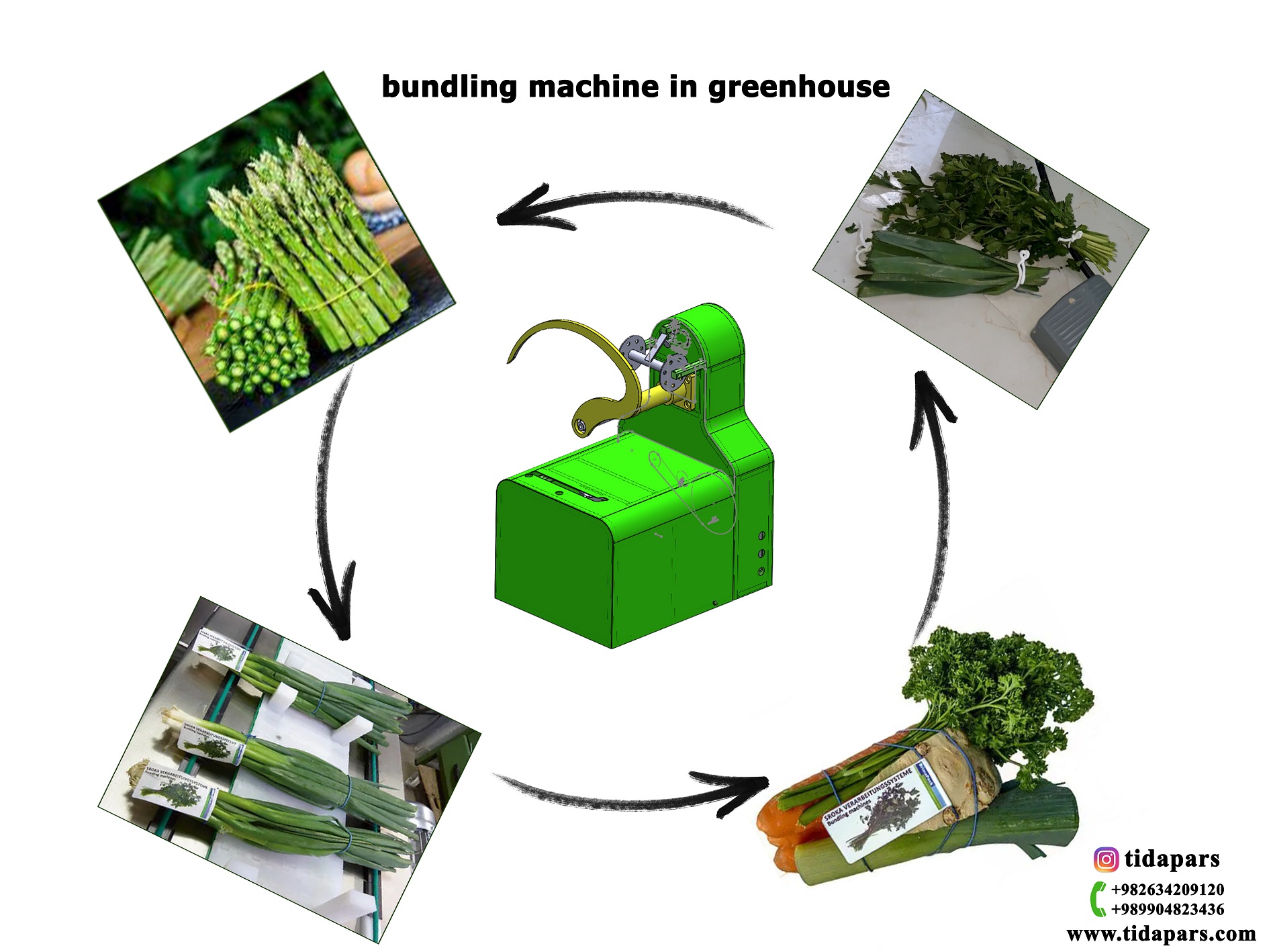

About “bundling machine” in greenhouse

A bundling machine in a greenhouse is a device used to bundle together harvested crops, such as flowers, vegetables, and fruits, into compact and uniform bundles. The machine can be used to tie together individual stems or bunches of produce, creating a neat and organized appearance that is more visually appealing and easier to transport.

Bundling machines are typically used in commercial greenhouses, where large quantities of crops are harvested and sold to retailers and wholesalers. The machine can improve efficiency and reduce labor costs by automating the bundling process, which would otherwise have to be done manually. The machine can also improve the consistency of the bundles, resulting in a more uniform and professional appearance.

There are different types of bundling machines available on the market, including manual machines and fully automated machines. Manual machines require operators to load the crops onto the machine and activate the bundling process manually, while fully automated machines can perform the entire process automatically, from loading to bundling and tying.

Overall, the bundling machine is a useful tool for commercial greenhouse growers who are looking to improve the efficiency and consistency of their harvesting process.

Sure, here are some additional details about bundling machines in greenhouses:

1. Types of bundling machines: There are several types of bundling machines available, including semi-automatic machines, fully automatic machines, and hand-held machines. Semi-automatic machines require manual loading of the produce, while the machine performs the bundling and tying process automatically. Fully automatic machines perform the entire process, from loading to bundling and tying, without any human intervention. Hand-held machines are operated by a worker who places the produce into the machine and operates the bundling mechanism manually.

2. Benefits of using bundling machines: One of the main benefits of using bundling machines is improved efficiency. The machines can bundle crops much faster than manual labor, which can save time and reduce labor costs. Additionally, bundling machines can produce uniform bundles of crops, which can be more visually appealing to customers and easier to transport.

3. Types of crops that can be bundled: Bundling machines can be used for a variety of crops, including flowers, herbs, vegetables, and fruits. For example, in the flower industry, bundling machines are commonly used to bundle roses, lilies, and other cut flowers.

4. Factors to consider when choosing a bundling machine: When choosing a bundling machine, it’s important to consider factors such as the type of crops being bundled, the size of the operation, and the level of automation required. Additionally, it’s important to consider the cost of the machine and the ongoing maintenance and repair costs.

5. Maintenance and safety considerations: Like any machine, bundling machines require regular maintenance to ensure optimal performance and safety. This may include cleaning and lubricating the machine, replacing worn parts, and performing regular safety checks. Additionally, operators should receive proper training on how to operate the machine safely and efficiently.

Can bundling machines be used for other crops besides flowers?

Yes, bundling machines can be used for a variety of different crops besides flowers. In fact, bundling machines are commonly used in the agriculture industry for bundling crops such as vegetables, fruits, and herbs.

For example, bundling machines can be used to bundle together vegetables such as asparagus, green beans, and carrots. The machine can wrap a single band around the bundle to keep the vegetables together, making them easier to transport and sell. Similarly, bundling machines can be used to bundle together fruits such as grapes, strawberries, and citrus fruits.

In the herb industry, bundling machines are commonly used to bundle together herbs such as cilantro, parsley, and basil. The machine can tie the herbs together at the stem, creating a neat and uniform bundle that is easier to handle and sell.

Overall, bundling machines can be used for a wide range of crops, as long as the crops can be bundled together in a way that is visually appealing and practical for transport and sale.

What factors should I consider when choosing a bundling machine?

There are several factors to consider when choosing a bundling machine, including:

1. Type of Material: The type of material you will be bundling is an important factor to consider when choosing a bundling machine. Different materials may require different types of machines, such as stretch film bundling machines for plastic products, strapping machines for metal products, or balers for hay or straw.

2. Volume of Production: The volume of production you need to achieve will also play a role in determining the type of bundling machine you need. If you have a high volume of production, you may need a machine with a higher capacity or faster processing speed to keep up with demand.

3. Available Space: The size of the space you have available for the bundling machine is also an important factor to consider. Some bundling machines, such as large balers, require a significant amount of space to operate effectively. But others, such as vegetable and flower bundling machines, are often small.

4. Cost: The cost of the bundling machine is also an important consideration. You should choose a machine that fits within your budget while still meeting your production needs.

5. Maintenance and Support: It is important to choose a bundling machine from a reputable manufacturer that offers maintenance and support services. This will help ensure that your machine runs smoothly and minimize downtime due to maintenance issues.

6. Automation: Some bundling machines can be automated, which can help increase efficiency and reduce labor costs. If you have a high volume of production, an automated machine may be a good option to consider.

By considering these factors, you can choose a bundling machine that is best suited for your specific needs and production requirements.

Can you provide examples of how bundling machine in a greenhouse reduce packaging costs?

Yes, bundling machines can reduce packaging costs in several ways. Here are a few examples:

1. Reduced need for individual packaging: When crops are bundled together using a bundling machine, they can be transported and sold as a single unit, rather than as individual stems or bunches. This can eliminate the need for individual packaging, such as sleeves or wraps, which can reduce packaging costs.

2. Improved use of packaging materials: When crops are bundled using a bundling machine, the bundles can be made more compact and uniform, which can help to optimize the use of packaging materials. For example, if a bundle of flowers is a consistent size and shape, it may be possible to use packaging materials that are more tailored to that size and shape, rather than using larger or more generic packaging materials.

3. Reduced labor costs: Bundling machines can help to automate the bundling process, which can reduce the need for manual labor. This can lower labor costs associated with preparing individual stems or bunches for sale, which can indirectly reduce packaging costs.

4. Reduced waste: Bundling machines can help to reduce waste associated with packaging materials. For example, if a bundling machine in a greenhouse is used to create compact and uniform bundles of flowers, it may be possible to use smaller or more efficient packaging materials that generate less waste than traditional packaging materials.

Overall, bundling machines can help to reduce packaging costs by optimizing the use of packaging materials, reducing the need for individual packaging, and lowering labor costs associated with preparing crops for sale.