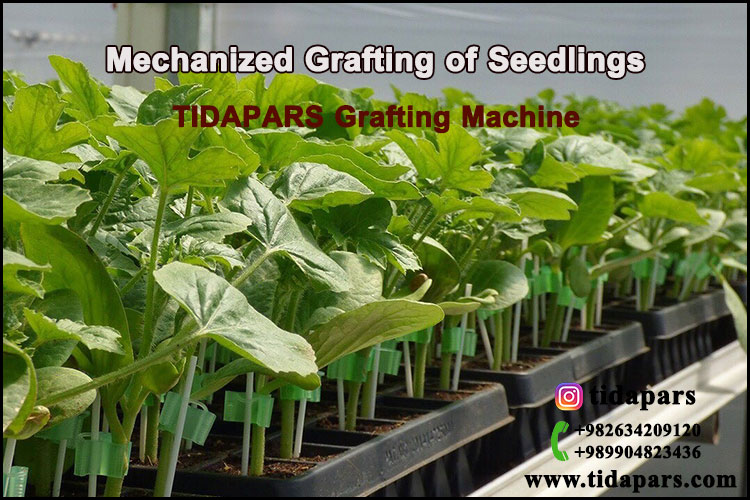

Mechanized Grafting of Seedlings

Mechanized grafting of seedlings is one of the most advanced innovations in modern agriculture. It allows farmers and greenhouse producers to combine two plants — a rootstock with strong resistance and a scion with desirable traits — resulting in seedlings that are healthier, stronger, and more productive.

What Is Grafted Seedling Production?

A grafted seedling is created by joining two compatible plant parts: the rootstock (which provides the root system and resistance) and the scion (which determines the quality and yield of the crop). This process produces plants that can better withstand soil diseases, salinity, and environmental stress.

Traditional Grafting vs. Mechanized Grafting

Traditionally, grafting is performed manually by skilled workers using a knife or clip. Although effective, it is time-consuming, labor-intensive, and costly for large-scale production. In contrast, mechanized grafting systems and robotic grafting machines perform the same process with high speed, precision, and uniformity — ideal for industrial greenhouse operations.

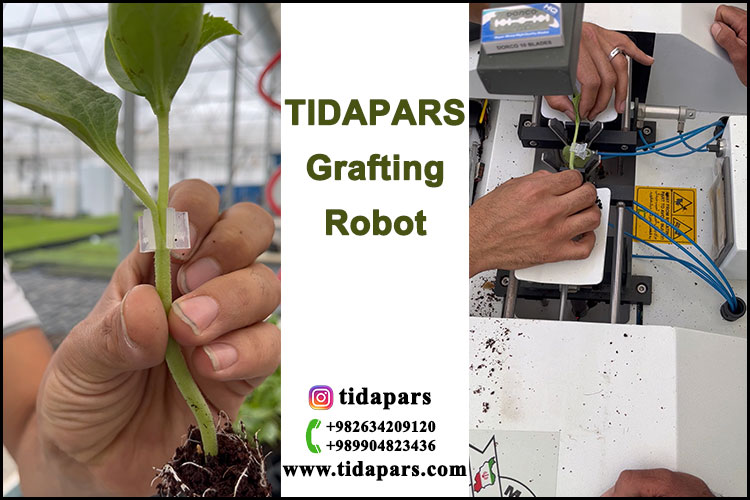

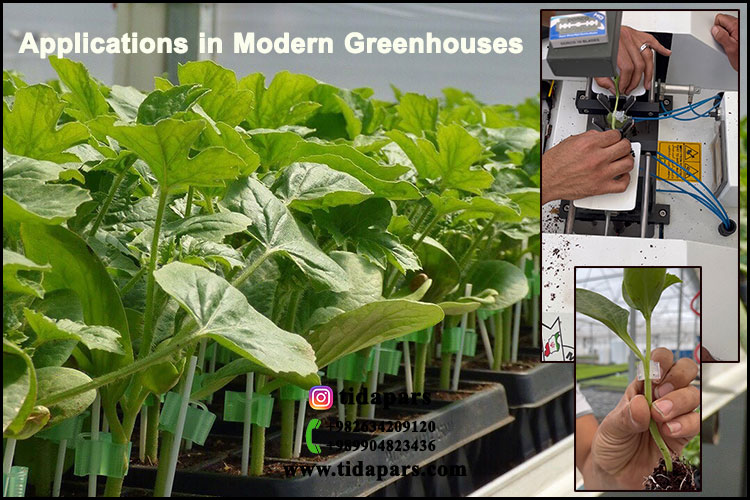

How Does Mechanized Grafting Work?

Mechanized grafting machines use advanced vision systems, mechanical arms, and sensors to cut, align, and join seedlings automatically. These machines can perform hundreds to thousands of grafts per hour while maintaining consistent quality and alignment accuracy. The result is a faster and more reliable grafting process suitable for large-scale seedling nurseries.

Key Stages of Mechanized Grafting:

- Automatic cutting of rootstock and scion stems

- Precise alignment of both plant parts

- Joining and clipping of the grafted area

- Humidity and temperature-controlled healing phase

Advantages of Mechanized Grafting

Using automated grafting systems offers multiple benefits to greenhouse producers:

- Increased productivity: Hundreds of grafts per hour with minimal labor.

- Higher uniformity: Every graft is performed with the same precision.

- Reduced costs: Less dependence on manual labor and reduced human error.

- Improved plant health: Stronger seedlings with higher resistance to soil-borne diseases.

- Better profitability: Efficient production and higher-quality crops lead to better returns.

TIDAPARS Mechanized Grafting Machine

TIDAPARS, one of the leading agricultural machinery manufacturers in Iran, designs and produces advanced mechanized grafting machines for vegetable seedlings such as tomato, eggplant, and pepper. These machines are engineered to handle high production volumes while ensuring precision and ease of operation.

Main Features of TIDAPARS Grafting Machine:

- Adjustable grafting speed for different crop types

- Precise cutting and positioning mechanism

- Compact design suitable for greenhouse use

- Easy maintenance and low power consumption

- Local technical support and spare parts availability

Applications in Modern Greenhouses

Mechanized grafting is widely used in modern greenhouses that produce seedlings for vegetables such as tomato, pepper, cucumber, and watermelon. The use of grafted seedlings has proven to increase crop yield, uniformity, and disease resistance while reducing pesticide usage.

Conclusion

The future of greenhouse seedling production lies in automation and precision technology. Mechanized grafting of seedlings not only ensures higher efficiency and quality but also contributes to sustainable agricultural development. By adopting advanced grafting machines like those produced by TIDAPARS, growers can achieve faster production cycles and healthier crops.

Grafting machines

Robotic grafting

Seedling grafting technology

Agricultural automation

TIDAPARS machines